ACTUATORS

November 26, 2007

by: jovial_cynic

by: jovial_cynic

I've been thinking about my CNC machine project for a little while, and now that I've made a few bucks selling my welded figurines, I've been on the prowl for information on how to build the machine in a cost-effective manner.

The two plans I picked up for building the CNC machine call for building slide actuators by using a threaded rod picked up at Home Depot. This is great for a shoestring budget and a lot of extra time, and also great if precision tolerances aren't an issue. However, I think that my budget allows for some machined pieces to help speed up the process.

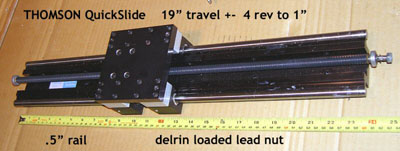

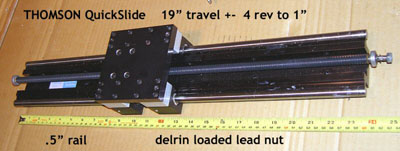

Hunting around on eBay, I found a 19" slide actuator for $80 shipped. Granted, 19" isn't terribly big, but I think it'll provide enough travel for me to make the things I have in mind.

I also picked up a 36" belt-drive rail for $163. It's a hefty price jump, but I think it'll be alright. I'm not sure I could find a 36" rail for much less; the 19" size is an odd size that I think most people probably aren't looking for.

($538)

The two plans I picked up for building the CNC machine call for building slide actuators by using a threaded rod picked up at Home Depot. This is great for a shoestring budget and a lot of extra time, and also great if precision tolerances aren't an issue. However, I think that my budget allows for some machined pieces to help speed up the process.

Hunting around on eBay, I found a 19" slide actuator for $80 shipped. Granted, 19" isn't terribly big, but I think it'll provide enough travel for me to make the things I have in mind.

I also picked up a 36" belt-drive rail for $163. It's a hefty price jump, but I think it'll be alright. I'm not sure I could find a 36" rail for much less; the 19" size is an odd size that I think most people probably aren't looking for.

($538)